| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : VIIPLUS

Model Number : oilless 2000 bushings

Certification : ISO 9001

Place of Origin : oilless bushing

MOQ : negotiable

Price : Negotiable

Payment Terms : T/T

Supply Ability : plug graphite bearings, China, manufacturers, suppliers, factory, wholesale, Metal Journal Bearing, PTFE Self Lubricating Bearing, Composite Thrust Bearing, Composite Self Lubricating Bushings, Graphite Alloy Bearing, Flange Cast Iron Bearing

Delivery Time : 7-25 work days

Packaging Details : EXPORT CARTON WOOD PALLET WOODEN CASE

Material : Solid Lubricant

Featrue : Maintenance

Lubricating : Solid Lubricant

Type : Bushing, Flange, Sliding Plate

Quality : High quality

Size : Customized

Bearing Bushing Factory Price : tiffany@viiplus.com

Self-lubricating Bearing Bushing Manufacturer : https://www.viiplus.com/

Oilless Bearing Manufacturer : https://www.bronzelube.com/

Manufacturer : bucha de bronze grafitado

High Light : Solid Bronze Plain Bearings, Graphite Flange Bronze Plain Bearings, Mining Machinery

Oilless Bushes : Oilless Bush. Copper Alloy. Straight type. SOB. Material Base Copper alloy (SO-2). Solid lubricant

Bush Bearings Manufacturers Suppliers Exporters : plain bearings. Long, maintenance-free service, manufactures bushings in various designs and from different materials. tiffany@viiplus.com, Bushings - Configure and purchase - https://www.viiplus.com/

Oilless Bush Supplier : www.VIIPLUS.com offers oilless bushings on their website [1]. You can visit their website to explore their product range and make inquiries.

The 2000 sintered multi-layer oilless bushes with dispersed solid lubricant are innovative components designed to provide exceptional wear resistance and durability in a wide range of industrial applications. These bushes are manufactured using a sintering process, which involves compressing and heating powdered metal materials to create a solid, porous structure.

The multi-layer design of these bushes allows for superior performance under high loads and speeds. Each layer is carefully crafted to optimize strength, stiffness, and lubrication properties. The dispersed solid lubricant within the material ensures smooth operation without the need for regular oiling or lubrication, significantly reducing maintenance requirements.

The sintered construction of these bushes also provides excellent heat resistance and corrosion resistance, ensuring reliable performance even in harsh environments. This makes them suitable for use in various machinery and equipment, including pumps, motors, and gearboxes.

The 2000 sintered multi-layer oilless bushes with dispersed solid lubricant offer a cost-effective and long-lasting solution for industrial applications that require high-performance bushings. Their unique design and material properties ensure smooth and efficient operation, reducing downtime and extending the lifespan of machinery and equipment.

Contact Us

To make an inquiry about or request for a catalog of OILLES bushings bearings, contact today!

(Graphite Embedded Low carbon Steel)

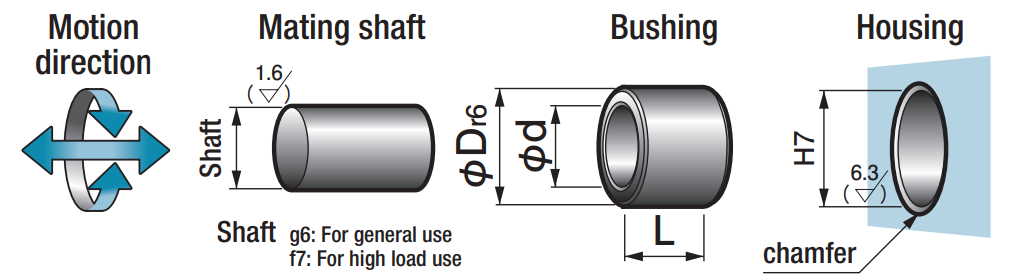

Specify Part No. by required I.D., O.D. and Length. (e.g.) I.D. is 35mm, O.D. is 44mm, and length is 50mm.

Oilles 2000 Bushings (High Precision type)

Oilles 2000 Flange Bushings (High Precision type)

Oilles 2000 Wear Plates 5mm Thickness

Oilles 2000 Wear Plates 10mm Thickness

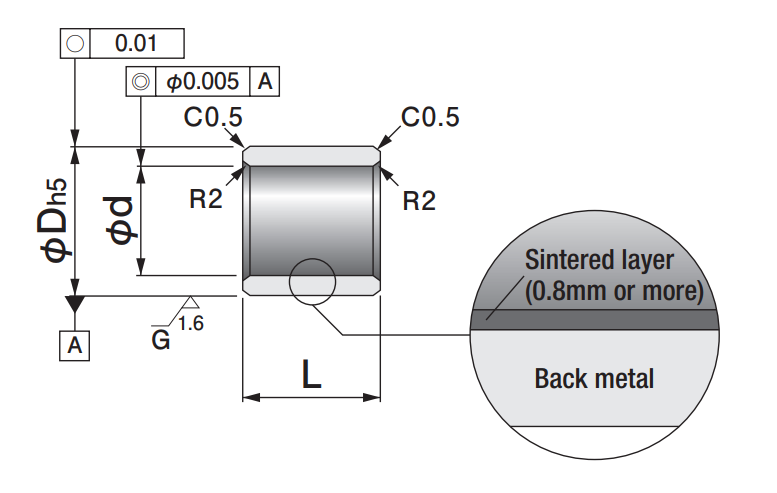

Oilles 2000 bushing sleeve are Sintered Multi-Layer Bearings bushing sleeve made up of sliding surfaces made of special sintered material and steel back metals. The solid lubricant made mainly of graphite is dispersed in the sintered layer, which is sintered and impregnated with oil.

Self-lubricating , Maintenance-free Bushing sleeve

Oilles 2000 bushing sleeve is a Sintered Multi-Layer Bearings bushing sleeve made of a special sintered material which forms the sliding surface and the steel material forms the support.

The sintered layers are of a special copper-nickel alloy containing a uniformly dispersed lubricating solid, the main component of which is graphite. Solid lubricants will be released onto the Sintered Multi-Layer Bearings bushing sleeve surface when wear occurs. This ensures a lower friction coefficient during operation.

In addition, these sintered layers are impregnated with oil. Applications covered include wear plates for automotive tools, industrial robots, wear plates for plastic injection molding machines and link Sintered Multi-Layer Bearings bushing sleeve, construction machinery, etc.

· Dispersed solid lubricant allows motions in any direction and offers superior performance for minute movements.

· Serviceable without the need for lubrication.

· Features superior load resistance, speed characteristics, and wear resistance.

· Standard Oilles 2000 bushing sleeve products and plates for additional machining are available in various sizes.

| Lubrication conditions | Dry | Periodic lubrication |

|---|---|---|

| Service temperature range (℃) | -40~+120 | -40~+120 |

| allowable max. contact pressure : P (N/mm2) | 24.5 | 49 |

| allowable max. velocity : V (m/s) | 0.50 | 1.00 |

| Allowable max. PV value (N/mm2・m/s) | 1.63 | 2.45 |

The values in parentheses are the static pressures of the Sintered Multi-Layer Bearings bushing sleeve , which are the pressures of the Sintered Multi-Layer Bearings in non-moving or very low-moving applications (≦ 0.0017 m / s).

| Density | —— | g/cm3 | 6.3 |

|---|---|---|---|

| Hardness | JIS K 7202-2 | HRM | 60-95 |

| Oil impregnation rate | —— | vol% | 12 |

· The value shown above are for sintered layer.

· The values shown above are typical values, not the standard values.

If the Bronze Bushing 2000 material is purchased and used by finishing it, it should be oil-impregnated after machining and then assembled in the housing. When the bushing sleeve Sintered Multi-Layer Bearings is stored for long or washed, it should be oil-impregnated again and then assembled in the housing. For the method, see the description about the oil impregnation method shown on page 250. Dip the machined bushing sleeveSintered Multi-Layer Bearings in lubricating oil for 24 hours or more before using it, if oil impregnation (by heating) is disabled.

| I.D. | O.D. | Length |

| class 7 to 8 | class 6 to 7 | class 8 to 9 |

| I.D. | O.D. | -0.1 Length L Tolerance -0.3 | ||||||||||

| φd | Tolerance | φD | Tolerance | 8 | 10 | 12 | 15 | 16 | 19 | 20 | 25 | 30 |

| 12 | +0.049 +0.038 | 18 | +0.034 +0.023 | 121808 | 121810 | 121812 | 121815 | 121816 | 121819 | 121820 | 121825 | 121830 |

| 13 | +0.053 +0.042 | 19 | +0.041 +0.028 | 131910 | 131912 | 131915 | 131920 | 131925 | 131930 | |||

| 14 | +0.053 +0.042 | 20 | +0.041 +0.028 | 142010 | 142012 | 142015 | 142020 | 142025 | 142030 | |||

| 15 | +0.053 +0.042 | 21 | +0.041 +0.028 | 152110 | 152112 | 152115 | 152116 | 152120 | 152125 | 152130 | ||

| 16 | +0.053 +0.042 | 22 | +0.041 +0.028 | 162210 | 162212 | 162215 | 162216 | 162219 | 162220 | 162225 | 162230 | |

| 18 | +0.053 +0.042 | 24 | +0.041 +0.028 | 182410 | 182412 | 182415 | 182416 | 182420 | 182425 | 182430 | ||

| 20 | +0.060 +0.047 | 28 | +0.041 +0.028 | 202810 | 202812 | 202815 | 202816 | 202819 | 202820 | 202825 | 202830 | |

| 20 | +0.060 +0.047 | 30 | +0.041 +0.028 | 203015 | 203016 | 203020 | 203025 | 203030 | ||||

| 25 | +0.065 +0.052 | 33 | +0.050 +0.034 | 253312 | 253315 | 253316 | 253320 | 253325 | 253330 | |||

| 25 | +0.065 +0.052 | 35 | +0.050 +0.034 | 253515 | 253516 | 253520 | 253525 | 253530 | ||||

| 28 | +0.065 +0.052 | 38 | +0.050 +0.034 | 283820 | 283825 | 283830 | ||||||

| 30 | +0.065 +0.052 | 38 | +0.050 +0.034 | 303812 | 303815 | 303820 | 303825 | 303830 | ||||

| 30 | +0.065 +0.052 | 40 | +0.050 +0.034 | 304015 | 304020 | 304025 | 304030 | |||||

| 35 | +0.076 +0.060 | 44 | +0.050 +0.034 | 354420 | 354425 | 354430 | ||||||

| 35 | +0.076 +0.060 | 45 | +0.050 +0.034 | 354520 | 354525 | 354530 | ||||||

| 40 | +0.076 +0.060 | 50 | +0.050 +0.034 | 405015 | 405020 | 405025 | 405030 | |||||

| 45 | +0.081 +0.065 | 55 | +0.060 +0.041 | 455530 | ||||||||

| 45 | +0.081 +0.065 | 60 | +0.060 +0.041 | 456030 | ||||||||

| 50 | +0.081 +0.065 | 60 | +0.060 +0.041 | 506020 | 506030 | |||||||

| 50 | +0.081 +0.065 | 62 | +0.060 +0.041 | 506230 | ||||||||

| 50 | +0.081 +0.065 | 65 | +0.060 +0.041 | 506530 | ||||||||

| 55 | +0.091 +0.072 | 70 | +0.062 +0.043 | 557030 | ||||||||

| 60 | +0.091 +0.072 | 74 | +0.062 +0.043 | 607430 | ||||||||

| 60 | +0.091 +0.072 | 75 | +0.062 +0.043 | 607530 | ||||||||

| 65 | +0.091 +0.072 | 80 | +0.062 +0.043 | |||||||||

| 70 | +0.096 +0.077 | 85 | +0.073 +0.051 | 708530 | ||||||||

| 70 | +0.096 +0.077 | 90 | +0.073 +0.051 | |||||||||

| 75 | +0.096 +0.077 | 90 | +0.073 +0.051 | |||||||||

| 75 | +0.096 +0.077 | 95 | +0.073 +0.051 | |||||||||

| 80 | +0.096 +0.077 | 96 | +0.073 +0.051 | |||||||||

| 80 | +0.096 +0.077 | 100 | +0.073 +0.051 | |||||||||

| 90 | +0.107 +0.085 | 110 | +0.076 +0.054 | |||||||||

| 100 | +0.107 +0.085 | 120 | +0.076 +0.054 | |||||||||

| I.D. | O.D. | Length L Tolerance 0 -0.3 | |||||||||||

| φd | Tolerance | φD | Tolerance | 16 | 20 | 25 | 30 | 40 | 50 | 60 | 80 | 100 | 120 |

| 12 | +0.011 +0.003 | 18 | 0 -0.008 | 121816 | 121825 | ||||||||

| 16 | +0.011 +0.003 | 22 | 0 -0.009 | 162216 | 162220 | 162230 | |||||||

| 20 | +0.013 +0.004 | 28 | 0 -0.009 | 202820 | 202830 | 202840 | |||||||

| 25 | +0.013 +0.004 | 33 | 0 -0.011 | 253325 | 253330 | 253340 | 253350 | ||||||

| 30 | +0.013 +0.004 | 38 | 0 -0.011 | 303830 | 303840 | 303850 | 303860 | ||||||

| 35 | +0.016 +0.005 | 44 | 0 -0.011 | 354440 | 354450 | 354460 | |||||||

| 40 | +0.016 +0.005 | 50 | 0 -0.011 | 405040 | 405050 | 405060 | |||||||

| 50 | +0.016 +0.005 | 62 | 0 -0.013 | 506250 | 506280 | ||||||||

| 60 | +0.019 +0.006 | 74 | 0 -0.013 | 607450 | 607460 | 607480 | |||||||

| 70 | +0.019 +0.006 | 85 | 0 -0.015 | 708550 | 7085100 | ||||||||

| 80 | +0.019 +0.006 | 96 | 0 -0.015 | 809650 | 809680 | 8096120 | |||||||

| 100 | +0.022 +0.007 | 120 | 0 -0.015 | 10012050 | 100120100 | 100120120 | |||||||

· Standard cylindrical bushes, flange bushes, thrust washers and slats are available.

· Lead-free type is also available

· All special designs are produced as required

Oilles 2000 bushing sleeve has been widely used in high load with lower friction and good wear resistance requested mechanical parts where oil given is difficult such as automotive die wear plate, industrial robots, injection wear plate, injection tie-bar bushes, construction machines self-lubricating bushing sleeve bearings etc.

|

|

2000 Sintered Multi Layer Oilless Bushes With Dispersed Solid Lubricant Images |